Sintering in powder metallurgy

What is sintering in powder metallurgy?

That was the question asked in a recent survey run among a sample of design engineers working at diverse firms in the manufacturing industry.

The result: no one was able to give a 100% correct definition of sintering and how the sintering mechanism works. Moreover, we have noticed that 3D printers have been added to create further confusion on the subject in recent years.

DOWNLOAD E-BOOK

Therefore, we have written this article to inform you, clearly and concisely, about what sintering is.

The result: no one was able to give a 100% correct definition of sintering and how the sintering mechanism works. Moreover, we have noticed that 3D printers have been added to create further confusion on the subject in recent years.

DOWNLOAD E-BOOK

Therefore, we have written this article to inform you, clearly and concisely, about what sintering is.

.jpg)

Definition

Let's start with a definition taken from the dictionary:

"Sintering is a process in which particles of a solid material in powder form, subjected to heating, approach and weld together, resulting in a compact piece of material. It is a widely used process in powder metallurgy [...] Typically, sintering is carried out at a temperature slightly below the melting temperature of the material." - Treccani

Sintering is employed to give strength and a solid structure to a given material, the goal is to shape the metal powders into a material for the final user. Sintering takes place in a unique, long hoven with diverse temperature zones.

Sintering process in powder metallurgy: 4 stages explained simply

We have provided a quick definition of what "sintering" is in metal powder metallurgy and the goals related to it. Now let’s dig deeper into the process in a simple and non-technical, yet thorough manner.

This process consists off the following four phases:

- The choice of alloy

- The pressing phase

- The sintering phase

- The finishing stage

Let's analyze each phase.

The choice of alloy

The first stage of the sintering process depends on the alloy we have selected, and it consists of the mixing of these chosen components in powder form.

This process depends on the characteristics we want to achieve for the product commissioned.

The blends can be either standard or special:

- Standard: most common alloys used for bar and plate drawing products.

- Special: tailor-made alloys for the product that the customer wants to produce.

But what is required to make these particular blends?

- Good knowledge of metallurgy.

- Experience on the behavior of the final product. (Result of a balanced and studied relationship between the components).

Even if a thorough understanding and planning of the product is required, most of the time empirical tests are necessary to obtain the right characteristics.

But this is not such a big deal.

Why?

Let’s go through the process together:

- You can mix the various components internally, creating a “trial and error” process.

- You create a large by chip sample of different mixtures with diverse mechanical characteristics.

- You can test each of them and choose which is the one that satisfies your needs.

- Definition of the most suitable blend to be connected in the archive with your part number.

The pressing phase

The second stage of the sintering process is called “the pressing phase”, and this is the moment in which the piece takes its shape.

The key elements of the pressing phase are:

- Double-acting hydraulic presses.

- The mold.

- The die.

Double-acting hydraulic presses act to deliver the “green” piece with the geometric characteristics required.

Pressing tonnages are gauged to fit the size of the parts, while the pressure is applied from both above and below.

But, first of all, a mold must be made. Mold employed in sintering processes are simpler and cheaper than the ones used in other manufacturing processes such as: M.I.M. (that we will define later on), plastic injection, molding, zamak or aluminium die casting and others.

The part of the mold that shapes the outer of your part is called “the die”. As an example: if your part has a pentagon-shaped outer outline, the die will be a block of steel that is round on the outside and has a pentagon-shaped through cavity. An upper and lower punch connected to the upper and lower cylinders of the press complete the die.

The result of this stage will be a block with a pentagonal shape. Even if it happens rarely, the height of the piece can be varied by working on the strokes of the punches.

A key advantage of sintering in powder metallurgy is the possibility to create very complex external shapes, and possibly internal ones as well. This is due to the fact that both the matrix that reflects the external shape, and the possible mobile punch placed inside to make a shaped hole, are made by wire EDM with centesimal tolerances.

To learn more, download the e-book, "How Metrology Can Help the Sintering Process."

DOWNLOAD E-BOOK

The sintering phase

What happens after the pressing phase?

After the pressing phase we can have three different situations depending on the size of the batches:

- Low batch (x<1.000 pieces): a physical operator takes the hexagonal block and deposits it in a box.

- Medium batch (1.000 - 20.000 pieces): a press automated system moves the piece towards a "slide" in order to deposit it in a box.

- Large batch (x>20.000 pieces): there is the possibility to use a robot to unload the piece into the box.

However, we are still talking about compressed powder (fragile and not yet sintered), this means that a physical operator is needed even in medium sized batches. In this case there is an increase in costs.

Returning to the production stage, the block has reached the box. Here the positioning depends on the shape, weight and other factors.

The standard options are three:

- In bulk.

- Arranged in rows and one above the other.

- Leaning rows on flat plates.

In the case of our pentagonal block, given its imprecise shape the first option is the conceivable one.

Once done the real sintering phase takes place with the moving of all the cassettes containing the parts through the oven. The pieces pass inside the furnace with a controlled atmosphere and go through different temperatures. The time also differs depending on the characteristics of the part.

Even if there is a cooling phase, the parts are still very hot when exiting the hoven. Therefore, remaining for a few hours before the next phase.

If tolerances are very tight a calibration step is required:

- The piece is placed back in the press.

- The piece is pressed and adjusted by means of a calibration die.

Calibration can also be carried out on manual presses, as a result this step can become more expensive than the part itself.

Now the production process is over.

Finishing Stage

After the 3 steps described in the sections above the sintered pieces lend themselves to various finishing processes:

- Oil impregnation.

- Impregnation in resin.

- Galvanizing.

- Nickel plating.

- Chrome plating.

- Steam oxidation.

In a nutshell, sintering in powder metallurgy is a heat treatment that, through 4 main steps, shapes metal powders with the aim of increasing its intrinsic strength and structural integrity, creating and providing the end-use parts.

Powder Metallurgy vs Metal Injection Molding vs Selective laser sintering

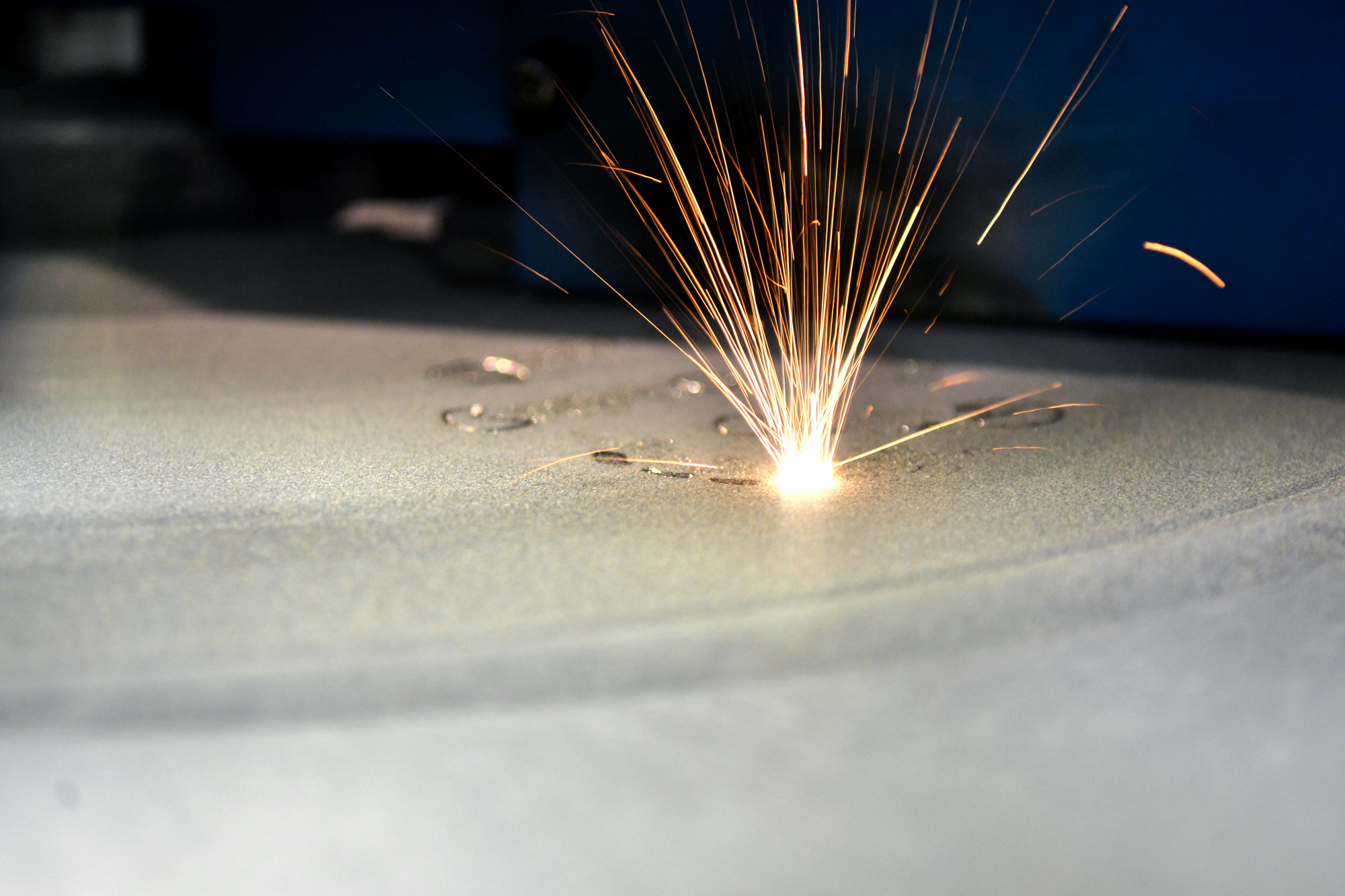

Sintering in powder metallurgy we have described above, is an old and very different process compared to the selective laser sintering.

Selective laser sintering advantages and disadvantages

The main differences are these two:

- 3D printers do not require a mold to shape the object.

- 3D printers are not usually suited for low-cost, mass production.

Sintering in powder metallurgy is a process that is more accurate and cheap than the 3D printer, yet we will all need one in the future.

Let’s now summarize in a table the advantages and disadvantages of Selective Laser Sintering compared to Powder Metallurgy.

Let’s now summarize in a table the advantages and disadvantages of Selective Laser Sintering compared to Powder Metallurgy.

| Powder Metallurgy | Selective Laser Sintering |

|

|

Metal Injection Molding vs Powder Metallurgy

Apart from the ambiguity defined in the above section, we will now define the main differences between sintering in powder metallurgy and metal injection molding (also known as M.I.M.).

- The final sintering process differs.

- The process differs dramatically in comparison with sintering technology, especially molding.

The process is divided into 3 steps:

- The initial metal alloy is 'injected' into the mold mixed with a polymer binding agent.

- The binder is eliminated, leaving some porosity.

- The part tends to "shrink", closing the porosity. That is the reason why the molds are made larger.

Let’s now summarize in a table the advantages and disadvantages of Metal Injection Molding compared to Powder Metallurgy.

| Powder Metallurgy | Metal Injection Molding |

|

|

Sintering advantages and disadvantages

We have gone through a comparison with the 2 main alternatives to sintering in powder metallurgy as a manufacturing process.

Now, we will highlight the advantages and limitations of this process.

PROS

- Porosity (perennial lubrication)

- Repeatability of large series

- Medium-complexity shapes (yet simple compared to the alternative processes)

- Green technology

- Little spec and low energy because we don't melt

- Good surface finish

- Vibration dampening for porosity

CONS

- Porosity makes the sintered part less strong.

- “Incomplete” end-use part due to a missed complexity in powder pressing.

We hope this article has been useful for you, we follow our customers in a step-by-step consulting approach and that’s the reason why we think that knowing their everyday work, together with the advantages and issues they face it’s the element that makes the difference.

To lear more about this topic, download our e-book on sintering.

DOWNLOAD E-BOOK