MELEGARI rejects-free goal: with Metrios "We know when it's time to change processing parameters".

aa

"If I get this part from Meccanica Melegari, I know it will be well done."

"I remember that I started off counting boxes of parts, then I moved into the office.

Being part of a family-run company is like having a tenure, you move from one department to the next, getting to know how everything works.

I'm Giulia Melegari, I'm the third generation of this family.

Today the company has undergone a transformation, now it has a fleet of ultra-modern machines".

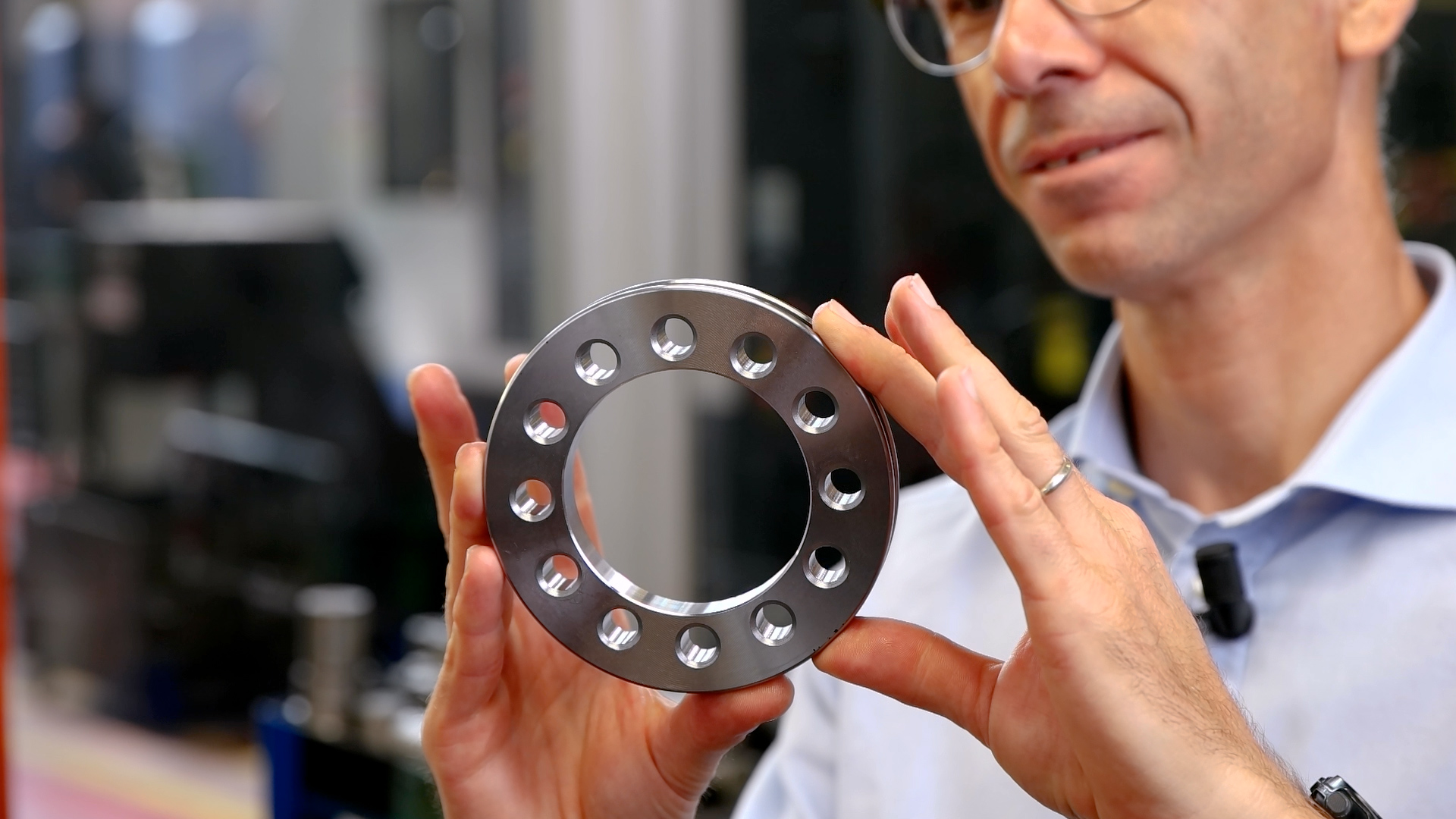

"Many of the 500 machined parts that we deal with here in Melegari are made out of steel.

This is one of the most popular, a coupling clutch sleeve.

We decided to purchase a Metrios Cross because in less than 32 seconds, we can inspect the concentricity of turning diameters, the size of the pin holes which must all be within one tenth of tolerance".

"Metrios is the perfect partner since we need to check these parts regularly".

"I'm Francesco Melegari, Production Manager here in Meccanica Melegari since 2003 and I'm also responsible for ISO 9001 2015 Quality Management.

My sister, cousin and I represent the third generation involved in this activity".

"My name's Elisabetta and I'm a lathe operator.

Right now, I'm working on this part designed for rolling.

I inspect one piece every 15/20 worked parts and I control the machine by myself. The spheres have to be perfect".

"These machines are so user friendly; all the operators can produce and check their work. This way they know when it's time to make any replacements or modify the working parameters on the machine".

"My grandfather always came to work in a suit, never without a tie. And when he arrived, you sure knew he was here!"

"He sent me into production to learn the ropes".

"We've advanced to more modern CNC machines that are computer-controlled and linked with the company's entire operating system on internal net.

In addition, since 2007 we have been collaborating with the earth-moving equipment industry, producing synchronizer rings that are assembled on the differential gears of trucks.

Over the past two years we have been investing heavily in automation and quality control in production".

"I consider Meccanica Melegari a personal asset.

I'm Simone Crema and I've been working here for 30 years, 25 of which have been dedicated to the quality control system.

Today competition is fierce. We have an edge thanks to various investments we have made in terms of machinery and personnel..."

"Every single operator, depending on whatever part they're working on, can regulate the frequency of inspection"

"...With Metrios, you just place the part on the stage and in about 20 seconds the operator can keep the whole process under control".

"This is what we're going to keep investing in - quality and Made in Italy products".

Wanna know more about Metrios?